-

- Shop Trucks & Trailers

- Shop Apparel

-

Shop Products

- Tools and Equipment

- Lighting

- Straps, Chains and Slings

-

Auto and Truck Accessories

- Tire and Wheel Supply

-

Exterior Accessories

- Suspension Upgrades

- Truck Fenders and Mounts

- Decals

- Horns and Sirens

- Backup Alarms

- Truck Body Trim and Hand Rails

- Mud Flaps

- Truck and Headache Racks

- Trailer Hitches and Receivers

- Push Bumpers and Hardware

- Truck Steps, Ladders and Handles

- Side View Mirrors

- Replacement Fuel Tanks

- Mico Brake Locks

- Throttle Controls

- Sunvisors

- Truck Service Lines and Accessories

- Interior Accessories

- Cargo Accessories

- Business Forms and Manuals

- Snow Plows and Parts

- Salt and Sand Spreaders and Parts

- Dump Bodies and Parts

- Diesel Particulate Filters and Gaskets

- Lift Gates and Parts

- Winches and Cables

- Toolboxes and Storage

- Battery Service

- Safety

-

Equipment and Trailer Parts

- Cylinder and Pin Replacements

- Control Handle Assemblies and Hardware

- Control Valve Bodies and Assemblies

- Control Cables

- Wheel Lift Parts

- Pivot Pins and Kits

- Wear Pads and Kits

- Bearing Pads and Kits

- Boom End Sheaves, Guides and Hardware

- Winch Cable Tie Backs

- Bed Lock Kits and Hardware

- Light Pylons

- Underlift Parts

- Fender Flares

- Car Hauler Trailer Parts

- Hose Trays

- Trailer Jacks and Plates

- Hydraulics

- Electrical

- Merchandise

-

Shop Parts by Diagram

Skip the search. Order parts faster right from our diagrams here.

-

- Shop Trucks & Trailers

- Shop Apparel

-

Shop Products

- Tools and Equipment

- Lighting

- Straps, Chains and Slings

-

Auto and Truck Accessories

- Tire and Wheel Supply

-

Exterior Accessories

- Suspension Upgrades

- Truck Fenders and Mounts

- Decals

- Horns and Sirens

- Backup Alarms

- Truck Body Trim and Hand Rails

- Mud Flaps

- Truck and Headache Racks

- Trailer Hitches and Receivers

- Push Bumpers and Hardware

- Truck Steps, Ladders and Handles

- Side View Mirrors

- Replacement Fuel Tanks

- Mico Brake Locks

- Throttle Controls

- Sunvisors

- Truck Service Lines and Accessories

- Interior Accessories

- Cargo Accessories

- Business Forms and Manuals

- Snow Plows and Parts

- Salt and Sand Spreaders and Parts

- Dump Bodies and Parts

- Diesel Particulate Filters and Gaskets

- Lift Gates and Parts

- Winches and Cables

- Toolboxes and Storage

- Battery Service

- Safety

-

Equipment and Trailer Parts

- Cylinder and Pin Replacements

- Control Handle Assemblies and Hardware

- Control Valve Bodies and Assemblies

- Control Cables

- Wheel Lift Parts

- Pivot Pins and Kits

- Wear Pads and Kits

- Bearing Pads and Kits

- Boom End Sheaves, Guides and Hardware

- Winch Cable Tie Backs

- Bed Lock Kits and Hardware

- Light Pylons

- Underlift Parts

- Fender Flares

- Car Hauler Trailer Parts

- Hose Trays

- Trailer Jacks and Plates

- Hydraulics

- Electrical

- Merchandise

-

Shop Parts by Diagram

Skip the search. Order parts faster right from our diagrams here.

Sealants

Sealants provide quick sealing solutions to stop leaks and prevent environmental contamination. Designed for oil, fuel, and chemical applications, they create a secure barrier in emergencies. Easy-to-apply formulas save time during roadside or shop incidents. Keep sealants as part of your spill control kit. Ensure fast containment and environmental protection every time.

Plug N' Dike Premix

SpillTech WoodPlugs

Plug N' Dike Plug Pattie with AntiFreeze

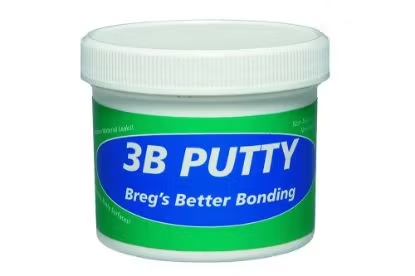

Breg's 3B Drum Putty

Plug N' Dike 10 lb Dry Granular Sealant

Quick Cable Battery Acid Spill Vehicle Kit

UltraTech Ultra-Drain Seal

Sealants for Fast and Reliable Leak Control

When a spill or leak occurs, immediate containment is critical to prevent environmental damage and downtime. Sealants provide an essential first line of defense by quickly plugging and sealing leaks in drums, tanks, pipes, and other equipment. Whether you’re managing an industrial site, service truck, or towing operation, having a reliable sealant on hand ensures you can respond fast and safely before a spill worsens.

Why Choose Industrial Leak Sealants

High-performance leak sealants are formulated to temporarily or permanently stop the flow of liquids, oils, fuels, and chemicals from damaged containers or fittings. Products in this category are ideal for emergency response, routine maintenance, and compliance with spill prevention protocols. Unlike standard adhesives or tapes, these specialized compounds expand or harden on contact, creating a secure seal even under pressure or on irregular surfaces.

Operators often keep sealants as part of a spill containment kit or hazmat response kit to address leaks before deploying absorbents or granular materials. Choosing the right product depends on the material type, container composition, and the environment where the leak occurs.

Top Leak Sealant Brands

At Zips.com, you’ll find trusted sealant solutions from industry leaders known for their reliability and speed in emergency applications:

- Plug N’ Dike – Known for their fast-acting clay-based sealants like the Plug N' Dike Premix, designed to instantly stop leaks on fuel and chemical containers without mixing or curing.

- Breg’s – Offering durable putty-style sealants such as Breg’s 3B Drum Putty, ideal for sealing small punctures or cracks in metal drums and tanks.

- SpillTech – Featuring specialty leak control items like SpillTech WoodPlugs, which can be hammered directly into holes or gaps for immediate fluid stoppage.

Each brand offers unique sealing technologies tailored to specific materials, from petroleum-based fluids to corrosive chemicals.

Choosing the Right Sealant for Your Application

When selecting a sealant, consider the fluid type (oil, fuel, or chemical), the surface material (metal, plastic, or fiberglass), and the urgency of the repair. Clay-based sealants like Plug N’ Dike’s are excellent for quick patching in the field, while putty-style options like Breg’s 3B are better suited for workshop repairs or long-term containment.

Spill response professionals often pair sealants with absorbent granules, sorbent pads, or booms to capture residual fluids after the leak is contained. Keeping these products together in a spill response kit ensures your team is always ready to handle leaks safely and efficiently.

Learn More About Spill Response Best Practices

For additional insights on containing and managing spills quickly, check out our blog post: Untimely Spills Require Timely Response. It covers real-world examples and practical steps to improve spill preparedness and compliance in the field.

Frequently Asked Questions

What are industrial sealants used for?

Industrial sealants are used to temporarily or permanently stop leaks in containers, tanks, or pipes holding oil, fuel, chemicals, or other liquids.

Can sealants work on both metal and plastic surfaces?

Yes, most emergency sealants are formulated to adhere to a variety of surfaces, including metal, fiberglass, and certain plastics, though compatibility should always be checked for specific chemicals.

Are sealants a permanent fix?

Some sealants provide a lasting solution, but most are designed for temporary containment until proper repairs can be made.

Can sealants be used in combination with absorbents or booms?

Absolutely. Sealants are often the first step in spill response, followed by absorbent materials to capture residual liquids.

How long does it take for a sealant to work?

Fast-acting sealants like Plug N’ Dike Premix work immediately upon application, while putty-based products may take a few minutes to cure depending on temperature and material type.