Winch Cable Accessories

Winch cable accessories include hooks, thimbles, and hardware to complete securement setups. These components enhance safety and reliability in winching operations. Built tough, they ensure long-lasting performance in demanding conditions. Use winch cable accessories for recovery, construction, and transport work.

Showing 50 items

- Price

-

-

-

-

-

- Grade

-

-

- Hook and Latch Type

-

-

- Hook Type

-

-

- Type

-

-

-

- Brand

-

-

-

-

-

-

-

-

-

-

-

- Chain Grade

-

- Hardware Type

-

-

-

-

-

-

- Hooks & Hardware Type

-

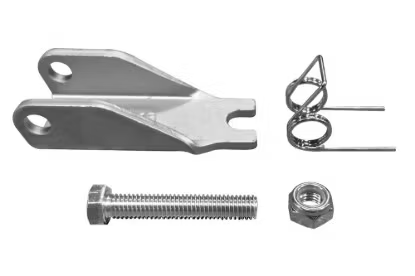

B/A Products Latch Kits

All-Grip Self-locking Swivel Hook G80

Aervoe Wire Rope, Chain and Cable Lube

Crosby 400 Wire Rope Lubricant, 12 oz.

Zip's Grade 80 Clevis Self-Locking Hook

All-Grip Wire Rope Clips

All-Grip Winch Cable Thimble

Discontinued items are not eligible for return. View Returns Policy

This is a winch cable thimble made of hot-dipped and galvanized steel from All-Grip.

- 4 options

- Hot-dipped and galvanized steel

Green Pin Open Wedge Socket with Safety Bolt

Crosby Terminator Wedge Socket

Zip's Synthetic Rope Thimble

Yoke G100 Clevis Self-Locking Hook

ESMET Electroline Safe-Line Clamp

Samson Fid Repair Kit

| Item # | Size |

|---|---|

| SR-9010160 | 1/4" |

| SR-9010240 | 3/8" |

| SR-9010280 | 7/16" |

| SR-9010320 | 1/2" |

| SR-9010360 | 9/16" |

| SR-9010400 | 5/8" |

| SR-9010480 | 3/4" |

| SR-9010560 | 7/8" |

Gunnebo-Johnson Safety Latch

Green Pin Wire Rope Clip

Aervoe HD Open Gear and Wire Rope Lube

All-Grip Sling Hook Latches Grade 100

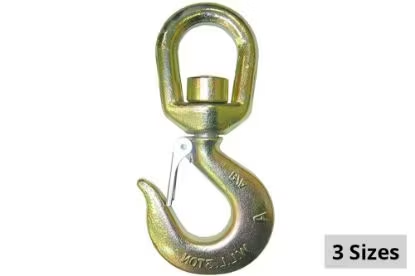

B/A Products Swivel Hoist Hooks w/ Latches

All-Grip Self-locking Clevis Hook G80

All-Grip Alloy Hooks Swivel

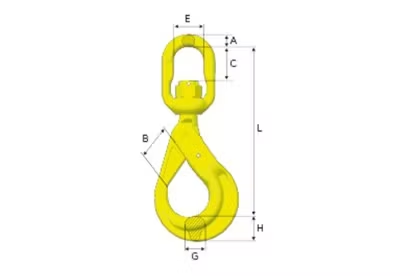

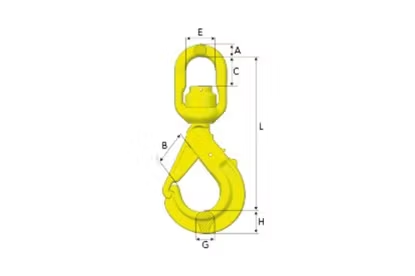

Gunnebo GrabiQ Swivel Safety Hook BKL

| Item # | GI-Z101114 | GI-Z101104 | GI-Z101028 | GI-Z101036 | GI-Z101044 | GI-Z101093 |

|---|---|---|---|---|---|---|

| Code | BKL-6-10 | BKL-7/8-10 | BKL-10-10 | BKL-13-10 | BKL-16-10 | BKL-18/20-10 |

| WLL lb* | 3,306 | 5,700 | 8,800 | 15,000 | 22,600 | 35,300 |

| L | 5.87 | 7.20 | 8.58 | 11.10 | 13.43 | 14.49 |

| B | 1.14 | 1.46 | 1.77 | 2.17 | 2.44 | 2.68 |

| C | 0.91 | 1.06 | 1.46 | 1.93 | 2.56 | 2.76 |

| E | 1.30 | 1.50 | 1.73 | 1.89 | 2.40 | 2.83 |

| A | 0.43 | 0.47 | 0.59 | 0.75 | 0.98 | 1.22 |

| G | 0.59 | 0.67 | 0.83 | 1.18 | 1.46 | 1.73 |

| H | 0.83 | 1.02 | 1.22 | 1.57 | 1.97 | 2.44 |

| Weight lb | 1.54 | 2.65 | 4.41 | 8.82 | 15.87 | 25.13 |

| Fulfills requirements in: EN 1677:2008 (WLL +25%), ASTM A952/A952M and AS 3776:2015. *Safety factor 4:1. All dimensions in inches. |

||||||

Metric

| Item # | GI-Z101114 | GI-Z101104 | GI-Z101028 | GI-Z101036 | GI-Z101044 | GI-Z101093 |

|---|---|---|---|---|---|---|

| Code | BKL-6-10 | BKL-7/8-10 | BKL-10-10 | BKL-13-10 | BKL-16-10 | BKL-18/20-10 |

| WLL tonnes* | 1.5 | 2.6 | 4.0 | 6.8 | 10.3 | 16.0 |

| L | 149 | 183 | 218 | 282 | 341 | 368 |

| B | 29 | 37 | 45 | 55 | 62 | 68 |

| C | 23 | 27 | 37 | 49 | 65 | 70 |

| E | 33 | 38 | 44 | 48 | 61 | 72 |

| A | 0.43 | 0.47 | 0.59 | 0.75 | 0.98 | 1.22 |

| G | 0.59 | 0.67 | 0.83 | 1.18 | 1.46 | 1.73 |

| H | 0.83 | 1.02 | 1.22 | 1.57 | 1.97 | 2.44 |

| Weight kg | 1.54 | 2.65 | 4.41 | 8.82 | 15.87 | 25.13 |

| Fulfills requirements in: EN 1677:2008 (WLL +25%), ASTM A952/A952M-02 and AS 3776:2015. *Safety factor 4:1. All dimensions in mm. | ||||||

Yoke G100 Eye Self Locking Hook

Zip's Wire Rope Clips

Samson Rope Synthetic Rope Thimble

Zip's Grade 100 Eye Self-Locking Hook

All-Grip Self-locking Eye Hook G80

B/a Products Latck Kit - 5/16" Slip Hook

All-Grip Alloy Hooks Eye

Gunnebo Johnson Sling Hooks Eye G80

Warn Winchline Dampener

Gunnebo GrabiQ Swivel Safety Hook BKLK

| Item # | GI-Z101116 | GI-Z101106 | GI-Z101030 | GI-Z101038 | GI-Z101046 | GI-Z101095 | GI-Z101294 | GI-Z101295 |

|---|---|---|---|---|---|---|---|---|

| Code | BKLK-6-10 | BKLK-7/8-10 | BKLK-10-10 | BKLK-13-10 | BKLK-16-10 | BKLK-18/20-10 | BKLK-22-10 OS | BKLK-26-10 OS |

| WLL lb* | 3,306 | 5,700 | 8,800 | 15,000 | 22,600 | 35,300 | 44,080 | 60,169 |

| L | 5.87 | 7.20 | 8.58 | 11.02 | 13.35 | 14.49 | 17.17 | 19.13 |

| B | 1.14 | 1.46 | 1.77 | 2.17 | 2.44 | 2.68 | 3.11 | 3.94 |

| C | 0.94 | 1.06 | 1.38 | 1.77 | 2.44 | 2.36 | 3.15 | 4.33 |

| E | 1.30 | 1.50 | 1.73 | 1.89 | 2.40 | 2.83 | 3.15 | 4.02 |

| A | 0.43 | 0.47 | 0.59 | 0.75 | 0.98 | 1.22 | 1.38 | 1.77 |

| G | 0.59 | 0.67 | 0.83 | 1.18 | 1.46 | 1.73 | 1.97 | 2.13 |

| H | 0.83 | 1.02 | 1.22 | 1.57 | 1.97 | 2.44 | 2.44 | 2.68 |

| Weight lb | 1.54 | 2.65 | 4.41 | 8.82 | 16.09 | 25.35 | 37.04 | 57.32 |

| Fulfills requirements in: EN 1677:2008 (WLL +25%), ASTM A952/A952M and AS 3776:2015. For larger sizes, see Classic Grade 8. *Safety factor 4:1. All dimensions in inches. | ||||||||

Metric

| Item # | GI-Z101116 | GI-Z101106 | GI-Z101030 | GI-Z101038 | GI-Z101046 | GI-Z101095 | GI-Z101294 | GI-Z101295 |

|---|---|---|---|---|---|---|---|---|

| Code | BKLK-6-10 | BKLK-7/8-10 | BKLK-10-10 | BKLK-13-10 | BKLK-16-10 | BKLK-18/20-10 | BKLK-22-10 OS | BKLK-26-10 OS |

| WLL tonnes* | 1.5 | 2.6 | 4.0 | 6.8 | 10.3 | 16.0 | 20.0 | 27.3 |

| L | 149 | 183 | 218 | 280 | 339 | 368 | 436 | 486 |

| B | 29 | 37 | 45 | 55 | 62 | 68 | 79 | 100 |

| C | 24 | 27 | 35 | 45 | 62 | 60 | 80 | 110 |

| E | 33 | 38 | 44 | 48 | 61 | 72 | 80 | 102 |

| A | 11 | 12 | 15 | 19 | 25 | 31 | 35 | 45 |

| G | 15 | 17 | 21 | 30 | 37 | 44 | 50 | 54 |

| H | 21 | 26 | 31 | 40 | 50 | 62 | 62 | 68 |

| Weight kg | 0.7 | 1.2 | 2.0 | 4.0 | 7.3 | 11.5 | 16.8 | 26.0 |

| Fulfills requirements in: EN 1677:2008 (WLL +25%), ASTM A952/A952M-02 and AS 3776:2015. For larger sizes, see Classic Grade 8. *Safety factor 4:1. All dimensions in mm. | ||||||||

B/A Products Yoke 1/2" Grade 80 Clevis Self-Locking Hook

Gunnebo Latch Kit RDEKN

| Item # | Code | Weight lb |

|---|---|---|

| GI-Z100445 | RDEKN- 6 / OKN / RH 1 | 0.07 |

| GI-Z100447 | RDEKN- 7/8 /LKN / RH 2 | 0.11 |

| GI-Z100450 | RDEKN-10 / LKN / RH 3 | 0.13 |

| GI-Z100449 | RDEKN-13 / LKN / RH 5 | 0.29 |

| GI-Z100217 | RDEKN-16 / LKN | 0.44 |

| GI-Z100453 | RDEKN-18/20 | 0.57 |

| GI-Z100452 | RDEKN-22 | 0.93 |

| GI-Z100742 | RDEKN-26 | 1.17 |

| GI-Z100743 | RDEKN-32 | 1.32 |

Metric

| Item # | Code | Weight kg |

|---|---|---|

| GI-Z100445 | RDEKN- 6 / OKN / RH 1 | 0.03 |

| GI-Z100447 | RDEKN- 7/8 /LKN / RH 2 | 0.05 |

| GI-Z100450 | RDEKN-10 / LKN / RH 3 | 0.06 |

| GI-Z100449 | RDEKN-13 / LKN / RH 5 | 0.13 |

| GI-Z100217 | RDEKN-16 / LKN | 0.20 |

| GI-Z100453 | RDEKN-18/20 | 0.26 |

| GI-Z100452 | RDEKN-22 | 0.42 |

| GI-Z100742 | RDEKN-26 | 0.53 |

| GI-Z100743 | RDEKN-32 | 0.60 |

Yoke 5/8" G100 Self-Locking Swivel Hook w/ Ball-Bearing Swivel

B/A Self Locking Swivel Hook, Grade 80, 5/16"

Crosby Clevis Self Locking Hook Grade 100

Gunnebo GrabiQ Safety Hook BKG

Available in the following sizes

| Item # | Size | WLL |

|---|---|---|

| GI-Z101100 | 5/16" | 5,700 lbs. |

| GI-Z101026 | 3/8" | 8,800 lbs. |

| GI-Z101034 | 1/2" | 15,000 lbs. |

| GI-Z101042 | 5/8" | 22,600 lbs. |

| GI-Z101091 | 3/4" | 35,300 lbs. |

| GI-Z101110 | 7/32" | 3,306 lbs. |

| GI-Z101098 | 9/32" | 4,500 lbs. |

Crosby S-1326 Positive Locking Alloy Swivel Hooks

Gunnebo GrabiQ Swivel Safety Hook with Griplatch LKBK

Gunnebo GrabiQ Swivel Safety Hook with Griplatch LBK

B/A Self Locking Clevis Hook, Grade 80, 1/2"

Gunnebo GrabiQ Swivel Latch Hook LKNK

| Item # | GI-Z101349 | GI-Z101350 | GI-Z101351 | GI-Z101352 | GI-Z101354 |

|---|---|---|---|---|---|

| Code | LKNK-7/8-10 | LKNK-10-10 | LKNK-13-10 | LKNK-16-10 | LKNK-22-10 |

| WLL lb* | 5,700 | 8,800 | 15,000 | 22,600 | 44,080 |

| For chain dim. | 9/32, 5/16 | 3/8 | 1/2 | 5/8 | 7/8 |

| L | 6.06 | 7.52 | 9.29 | 11.54 | 15.75 |

| B | 1.10 | 1.38 | 1.57 | 2.09 | 2.91 |

| C | 1.10 | 1.38 | 1.77 | 2.44 | 3.15 |

| E | 1.50 | 1.73 | 1.89 | 2.40 | 3.15 |

| A | 0.47 | 0.59 | 0.75 | 0.98 | 1.38 |

| G | 0.71 | 0.91 | 1.10 | 1.34 | 1.69 |

| H | 0.94 | 1.22 | 1.50 | 1.69 | 2.64 |

| Weight lb | 1.98 | 3.53 | 7.28 | 12.3 | 31.5 |

| Fulfills requirements in: EN 1677:2008 (WLL +25%), ASTM A952/A952M and AS 3776:2015. *Safety factor 4:1. All dimensions in inches. | |||||

Metric

| Item # | GI-Z101349 | GI-Z101350 | GI-Z101351 | GI-Z101352 | GI-Z101354 |

|---|---|---|---|---|---|

| Code | LKNK-7/8-10 | LKNK-10-10 | LKNK-13-10 | LKNK-16-10 | LKNK-22-10 |

| WLL tonnes* | 2.6 | 4.0 | 6.8 | 10.3 | 20.0 |

| For chain dim. | 7, 8 | 10 | 13 | 16 | 22 |

| L | 154 | 191 | 236 | 293 | 400 |

| B | 28 | 35 | 40 | 53 | 74 |

| C | 28 | 35 | 45 | 62 | 80 |

| E | 38 | 44 | 48 | 61 | 80 |

| A | 12 | 15 | 19 | 25 | 35 |

| G | 18 | 23 | 28 | 34 | 43 |

| H | 24 | 31 | 38 | 43 | 67 |

| Weight kg | 0.9 | 1.6 | 3.3 | 5.6 | 15.1 |

| Fulfills requirements in: EN 1677:2008 (WLL +25%), ASTM A952/A952M-02 and AS 3776:2015. *Safety factor 4:1. All dimensions in mm. | |||||

Gunnebo GrabiQ Swivel Latch Hook LKN

| Item # | GI-Z101345 | GI-Z101346 | GI-Z101347 | GI-Z101348 |

|---|---|---|---|---|

| Code | LKN-7/8-10 | LKN-10-10 | LKN-13-10 | LKN-16-10 |

| WLL lb* | 5,700 | 8,800 | 15,000 | 22,600 |

| For chain dim. | 9/32, 5/16 | 3/8 | 1/2 | 5/8 |

| L | 6.10 | 7.56 | 9.37 | 11.61 |

| B | 1.10 | 1.38 | 1.57 | 2.09 |

| C | 1.10 | 1.46 | 1.85 | 2.56 |

| E | 1.50 | 1.73 | 1.89 | 2.40 |

| A | 0.47 | 0.59 | 0.75 | 0.98 |

| G | 0.71 | 0.91 | 1.10 | 1.34 |

| H | 0.94 | 1.22 | 1.50 | 1.69 |

| Weight lb | 1.76 | 3.31 | 6.83 | 11.7 |

| Fulfills requirements in: EN 1677:2008 (WLL +25%), ASTM A952/A952M and AS 3776:2015. *Safety factor 4:1. All dimensions in inches. |

||||

Metric

| Item # | GI-Z101345 | GI-Z101346 | GI-Z101347 | GI-Z101348 |

|---|---|---|---|---|

| Code | LKN-7/8-10 | LKN-10-10 | LKN-13-10 | LKN-16-10 |

| WLL tonnes* | 2.6 | 4.0 | 6.8 | 10.3 |

| For chain dim. | 7, 8 | 10 | 13 | 16 |

| L | 155 | 192 | 238 | 295 |

| B | 28 | 35 | 40 | 53 |

| C | 28 | 37 | 47 | 65 |

| E | 38 | 44 | 48 | 61 |

| A | 12 | 15 | 19 | 25 |

| G | 18 | 23 | 28 | 34 |

| H | 24 | 31 | 38 | 43 |

| Weight kg | 24 | 1.5 | 3.1 | 5.3 |

| Fulfills requirements in: EN 1677:2008 (WLL +25%), ASTM A952/A952M-02 and AS 3776:2015. *Safety factor 4:1. All dimensions in mm. |

||||

Gunnebo GrabiQ Shank Safety Hook BKT

| Item # | GI-Z1011020 | GI-Z1010710 | ||

|---|---|---|---|---|

| Code | BKT-7/8-10 | BKT-13-10 | ||

| WLL lb* |

5,700 | 15,000 | ||

| A | 4.37 | 6.30 | ||

| L | 1.46 | 2.17 | ||

| B | 1.85 | 3.03 | ||

| E | 0.94 | 1.34 | ||

| F | 0.51 | 0.79 | ||

| G | 0.67 | 1.18 | ||

| H | 1.02 | 1.54 | ||

| Weight lb | 1.98 | 6.61 | ||

| Fulfills requirements in: EN 1677:2008 (WLL +25%), ASTM A952/A952M and AS 3776:2015. d min = the smallest permitted shank dimension after machining. Note! After machining of the shank, proof loading must be carried out. *Safety factor 4:1. All dimensions in inches. |

||||

Metric

| Item # | GI-Z1011020 | GI-Z1010710 | ||

|---|---|---|---|---|

| Code | BKT-7/8-10 | BKT-13-10 | ||

| WLL tonnes* |

2.6 | 6.8 | ||

| L | 111 | 160 | ||

| B | 37 | 55 | ||

| L1 | 47 | 77 | ||

| D | 24 | 34 | ||

| dmin | 13 | 20 | ||

| G | 17 | 30 | ||

| H | 26 | 39 | ||

| Weight kg | 0.9 | 3.0 | ||

| Fulfills requirements in: EN 1677:2008 (WLL +25%), ASTM A952/A952M and AS 3776:2015. d min = the smallest permitted shank dimension after machining. Note! After machining of the shank, proof loading must be carried out. *Safety factor 4:1. All dimensions in mm. |

||||

Gunnebo GrabiQ Safety Hook BKD

| Item # | GI-Z101154 | GI-Z101155 | GI-Z101156 |

|---|---|---|---|

| Code | BKD-13-10 | BKD-16-10 | BKD-18/20-10 |

| WLL lb* |

15,000 | 22,600 | 35,300 |

| A | 0.79 | 1.02 | 1.18 |

| L | 8.15 | 10.00 | 11.38 |

| B | 1.73 | 1.89 | 2.24 |

| E | 1.73 | 2.20 | 2.36 |

| F | 0.63 | 0.79 | 0.87 |

| G | 1.18 | 1.46 | 1.73 |

| H | 1.57 | 1.97 | 2.44 |

| Weight lb | 7.05 | 12.79 | 20.06 |

| Fulfills requirements in: EN 1677:2008 (WLL +25%), ASTM A952/A952M and AS 3776:2015. *Safety factor 4:1. All dimensions in inches. | |||

Metric

| Item # | GI-Z101154 | GI-Z101155 | GI-Z101156 |

|---|---|---|---|

| Code | BKD-13-10 | BKD-16-10 | BKD-18/20-10 |

| WLL tonnes* |

6.8 | 10.3 | 16.0 |

| A | 20 | 26 | 30 |

| L | 207 | 254 | 289 |

| B | 44 | 48 | 52 |

| E | 44 | 56 | 60 |

| F | 16 | 20 | 22 |

| G | 30 | 37 | 46 |

| H | 40 | 50 | 62 |

| Weight kg | 3.2 | 5.8 | 9.1 |

| Fulfills requirements in: EN 1677:2008 (WLL +25%), ASTM A952/A952M-02 and AS 3776:2015. *Safety factor 4:1. All dimensions in mm. | |||

Winch Cable Accessories Buying Guide

When it comes to recovery and towing operations, a winch cable is only as strong and reliable as the accessories that support it. The Winch Cable Accessories category at Zips.com brings together the essential components that help extend the life, safety, and performance of your cable system. Whether you’re maintaining steel wire rope, synthetic line, or hybrid setups, the right accessories ensure consistent pulling strength and reliable operation every time.

Why Choose Quality Winch Cable Accessories

Your winch cable operates under extreme tension and harsh environments. Investing in quality accessories minimizes downtime and damage caused by corrosion, abrasion, or improper rigging. Accessories like cable hooks, lubricants, and safety tie backs not only protect the winch line but also improve operator safety and overall efficiency.

Professionals in towing, recovery, and off-road applications rely on these components to maintain smooth operation — from roadside recoveries to heavy-duty winch pulls. Choosing durable, corrosion-resistant, and properly rated accessories ensures your equipment performs safely under pressure.

Explore the Full Range of Winch Cable Accessories

This category covers all the tools and parts that keep your winch cable in top condition. Here’s what you’ll find within this section:

- Winch Cable Lubricants: Reduce friction and protect your cable from wear caused by repeated use and exposure to the elements. Proper lubrication helps extend cable life and ensures smoother spooling.

- Winch Cable Hooks and Latches: Secure, connect, and release loads safely. Designed for reliability, these components are vital for safe towing and recovery operations.

- Winch Cable Hardware: Essential connection and mounting components, including clamps, thimbles, and ferrules, that guarantee a secure setup and stable performance under load.

Each sub-category provides specific tools and products designed for different stages of cable maintenance and use, allowing you to select the right part without overlapping with related subpages.

Top Considerations When Shopping for Winch Cable Accessories

Before purchasing, consider these key factors to make sure you’re selecting the right accessories for your application:

- Cable Type: Steel and synthetic winch lines have different compatibility needs for hooks, lubricants, and hardware.

- Load Capacity: Always match the rated strength of your accessories to your winch’s pulling power.

- Environment: Choose corrosion-resistant materials like zinc-plated or stainless steel hardware for long-term performance in outdoor conditions.

- Maintenance Routine: Regular cleaning, lubrication, and inspection of cable connections significantly improve lifespan and safety.

By pairing the right accessories with your winch cable system, you can reduce the risk of failure and increase your operational reliability on every pull.

Expert Insight and Industry Support

Zips.com carries a comprehensive selection of winch cable accessories from trusted brands across the towing and recovery industry. Each product meets the performance and safety demands of professional operators who depend on reliable gear day in and day out.

Whether you’re outfitting a new setup or upgrading your existing equipment, our catalog includes every detail you need to maintain dependable cable operation — from first pull to final recovery.

FAQ: Winch Cable Accessories

What are winch cable accessories used for?

Winch cable accessories are used to maintain, protect, and secure winch cables. They include parts like hooks, lubricants, clamps, and tie backs that ensure safe operation and extend cable life.

Can I use the same accessories for steel and synthetic winch cables?

Not always. Some components, like lubricants or clamps, are designed specifically for either steel or synthetic lines. Always check the product specifications to ensure compatibility.

How often should I lubricate my winch cable?

For steel cables, lubrication should be applied regularly—especially after heavy use or exposure to water. Synthetic lines typically require cleaning and drying instead of lubrication.

Why is it important to use rated hooks and hardware?

Using properly rated components ensures that your winch system can handle its maximum load safely. Mismatched or unrated hardware can fail under tension and cause damage or injury.

What’s the best way to store a winch cable when not in use?

Use a cable tie back or retention system to secure the line neatly and prevent kinks or frays. Keep the winch cable clean and dry when stored for extended periods.