Hooks and Hardware

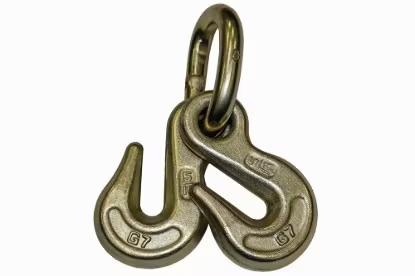

Explore our extensive selection of master links and rigging hardware, including oblong and pear-shaped master links from top manufacturers like B/A Products, Crosby, Miller, and more. These essential components provide versatile and reliable solutions for a wide range of towing and lifting applications. At Zip’s AW Direct, you’ll find grab hooks, foundry hooks, self-locking hooks, sling hooks, and slip hooks. Whether you’re assembling chains for heavy-duty lifting or need reliable master links, omega links, or couplings, Zip’s has you covered. For detailed information on each product’s capacities and working load limits (WLL), please refer to the specific product descriptions.

Showing 224 items

-

Non-Customizable Register Forms

Non-Customizable Register Forms

-

Light, Dash, Single, Sync Amb

Light, Dash, Single, Sync Amb

-

Phoenix Utility Can

Phoenix Utility Can

-

Phoenix Mud Flap

Phoenix Mud Flap

-

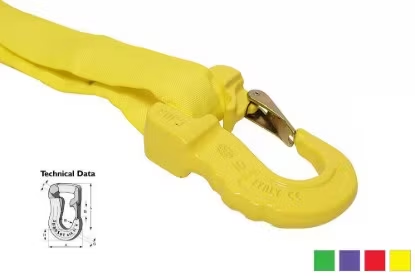

Zip's Strap with Snap Hook

Zip's Strap with Snap Hook

-

Goodall Welding Cable

Goodall Welding Cable

-

B/A Products Roller

B/A Products Roller

-

Ecco 22" LED Interior Light

Ecco 22" LED Interior Light

-

Jerr-Dan Bumper

Jerr-Dan Bumper

-

Ecco 13" LED Interior Light

Ecco 13" LED Interior Light

-

Ecco 18" LED Interior Light

Ecco 18" LED Interior Light

-

Ecco 12" LED Interior Light

Ecco 12" LED Interior Light

-

Code 3 Portable Blue/White LED Worklight

Code 3 Portable Blue/White LED Worklight

-

Code 3 Square 1450 Lumens LED Flood Light

Code 3 Square 1450 Lumens LED Flood Light

B/A Products Twist Lock Grab Hooks G80

Zip's Grade 100 Coupling Link

Yoke G100 Clevis Foundry Hook

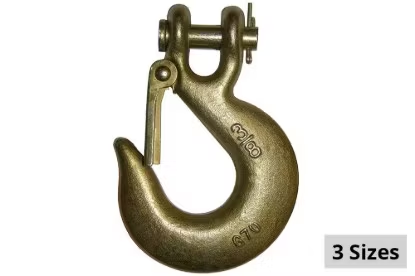

Zip's Grade 70 Clevis Grab Hook

Zip's Grade 70 Clevis Slip Hook

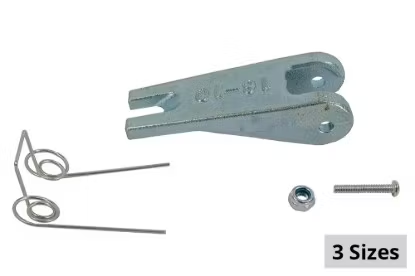

Zip's Grade 70 Clevis Slip Hook Latch Kit

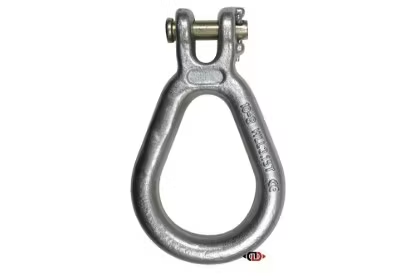

Zip's Grade 100 Oblong Link

Zip's Grade 80 Clevis Grab Hook

Durabilt 3.15 Ton 3/8" Forged Combo Clevis Pear Link

Zip's Grade 100 Clevis Cradle Grab Hook

Zip's Grade 100 Clevis Sling Hook

Zip's Grade 80 Coupling Link

All-Grip Cluster Assembly w/ Grab R T and Mini J Hook

B/A Products Container Eye Link Standard

B/A Products Frame Hook

All-Grip Replacement Hook Latch

Zip's Grade 80 Omega Link

Zip's Cluster Assembly with Grab, R, T, and Mini J Hook

B/A Products J-Hook, 15" Grade 70, Forged Clevis

Yoke G100 Coupling Link

B/A Products Clevis Slip Hooks w/ Latches G70

B/A Products Grab Hooks on Pear Link

Yoke G100 Clevis Grab Hook

Yoke G100 Forged Oblong Master Link

Zip's Grade 100 Slip Hook Replacement Latch Kits

B/A Products Grade 70 Mini J and Grab Hook

Yoke Sling Hooks w/ Latches Clevis G100

Ancra Clevis Grab Hook

Zip's Grade 100 Eye Foundry Hook

B/A Products J-Hooks Clevis G70

B/A J-Hook, Grade 80, 15" Clevis

B/A Products Grade 70 Double Clevis Links

Zip's Grade 80 Clevis Sling Hook

B/A Products Twist Lock Slip Hooks G70

B/A Products Grab T and Mini J Hooks on Oblong Link

All-Grip J Hook Long w/ Ring Link G70

All-Grip Datsun Mini J Hook on a Ring

Yoke Shipping Container Hooks

Zip's Grade 80 Eye Foundry Hook

Yoke G100 Clevis Cradle Grab Hook

Zip's Cluster Assembly with R, T, and Mini J Hook

B/A Products Container Eye Link Web Sling

B/A Products Twist Lock Cradle Grab Hooks G100

Yoke G100 Clutch Sling Hook

Zip's Cluster Assembly with Grab and Mini J Hook

B/A J-Hook, 8" Grade 70, Forged on a Link

All-Grip Weldable Grab Hook

Zip's Grade 80 Clevis Slip Hook Latch Kit

B/A Products R,T, and Mini J Hooks on Oblong Link

B/A Products 3/8" G70 Clevis Grab Hook

All-Grip Round Sling Hooks

SafeAll Grade 70 Clevis Grab Hook

All-Grip G70 Forged Mini J Hook

B/A T and Mini J Hooks on Oblong Link

B/A Products Grab Hooks on Link

Yoke G80 Oblong Master Link

Crosby Master Link 1 1/4" - Domestic

B/A Products J Hooks Forged Grade 70

Hooks and Hardware Buying Guide

When you’re building or maintaining a rigging, lifting, or recovery system, the hardware you choose determines how safe, durable, and easy-to-use the whole setup will be. This Hooks and Hardware category brings together core components like hooks, couplings, and links so you can spec a complete system that matches your load, environment, and workflow.

Why quality hardware matters

Good rigging hardware reduces risk, speeds up operations, and lowers long-term costs. A properly rated hook or coupling prevents unexpected failure, keeps working load limits consistent across the system, and makes inspections and replacement straightforward. Whether you’re in towing, construction, material handling, or industrial maintenance, choosing the right hooks and hardware is the difference between a secure lift and a costly incident.

You can explore each subcategory directly: Hooks, Couplings, Links.

Top brands carried

We stock industry-trusted manufacturers known for consistent performance and clear specification data like B/A Products, Yoke, Zip’s and Gunnebo.

Popular hook and hardware types:

- Grab hooks: for shortening or anchoring chains.

- Cradle grab hooks: reduce deformation by supporting the chain link.

- Self-locking hooks: automatically lock under load for secure lifts.

- Foundry hooks: wide throat for fast connections in industrial settings.

- Alloy coupling links: versatile connectors for chain and sling assemblies.

- Oblong master links & omega links: used as master attachments for multi-leg slings.

How to choose the right hardware

- Match the grade to the task. Grade 80 is common for recovery and general rigging; Grade 100 is a step up for heavier, high-demand lifting.

- Confirm working load limits (WLL). Every component must meet or exceed the required WLL for the whole assembly.

- Size for compatibility. Hook throat, coupling opening, and link dimensions must fit the chain or sling diameter.

- Pick the right style for the application. Example: self-locking hooks for overhead lifts; grab hooks for load securement.

- Consider environment and finish. Corrosion-resistant coatings or stainless options for marine or corrosive environments.

- Ease of inspection & replacement. Forged, stamped markings and clear WLL labels speed inspections and compliance checks.

Applications and industries

Hooks and hardware in this category are commonly used for:

- Towing and recovery

- Overhead lifting and rigging

- Transport load securement

- Construction & material handling

- Industrial maintenance and rigging operations

Compatibility & system thinking

A safe rig starts with matched components. Pair hooks and couplings with the appropriate chains or slings. Don’t mix grades or sizes. If you’re upgrading one component, it’s a good time to inspect and, if needed, replace the mating hardware so the entire assembly meets the same WLL and safety standard. Shop chains Shop slings:

Inspection & maintenance tips

- Perform a visual inspection before each use. Look for deformation, cracks, corrosion, or wear.

- Check stamped markings and WLL tags for legibility.

- Replace hardware with any visible damage. Do not attempt field repairs.

- Store dry and hang or rack pieces to avoid kinks and corrosion.

- Follow manufacturer torque/assembly guidance when closing coupling links or installing components.

Frequently asked questions (FAQ)

What’s the difference between Grade 80 and Grade 100 hardware?

Grade 100 is made from higher-strength alloy steel and typically has a higher working load limit (WLL) than Grade 80. Grade 100 is preferred for heavier lifts or tighter safety margins; Grade 80 is still widely used for recovery and many rigging applications.

Can I mix Grade 80 and Grade 100 components in the same assembly?

No. Mixing grades can create weak links in your rigging. All components in a load-bearing assembly should be of equal or greater rated capacity and compatible by design.

How do I choose between a grab hook and a self-locking hook?

Grab hooks are suited for chain shortening and transport securement. Self-locking hooks are designed for overhead lifting and applications where automatic locking under load improves safety.

Are coupling links suitable for overhead lifting?

Yes, but only if the coupling link is specifically rated and marked for lifting applications. Always verify the coupling’s WLL and compatibility with the chain grade and sling configuration.

How often should hooks and couplings be inspected?

Do a quick visual check before every use and a formal inspection at regular intervals determined by usage and regulatory standards. Replace any component that shows deformation, cracking, excessive wear, or corrosion.

Where can I find compatible chains or slings to pair with new hooks and couplings?

We recommend pairing hardware with matching chains and slings from our Chains and Slings categories to ensure grade and WLL compatibility.