Winches and winch lines are valuable tools across a variety of industries and applications, including towing and recovery, transportation, agriculture, construction, oil and gas and off-road recreation.

Over the next couple of weeks, we are going to look at the different types of winches and winch lines out there to discuss what you need to look for when upgrading your equipment or ordering new. Today, we’ll touch on the five winch line types available

from Zip's AW Direct.

- Synthetic Rope

- Fiber Core Wire Rope

- Steel Core Wire Rope

- Super Swaged Wire Rope

- Super Flex Wire Rope

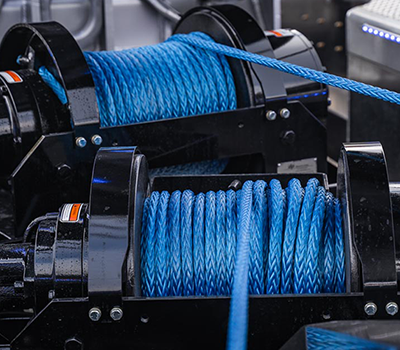

Synthetic Winch Lines

The first kind of winch line we’ll look at is Synthetic. Gaining in popularity in the towing & recovery industry, this braided fiber rope has been around commercial applications for decades with a proven track record in many

industries, according to Jeff Lechtenberg, product manager at Zip’s AW Direct.

Zip’s stocks diameter sizes ranging from 5/16” to 7/8” and are available in lengths up to 250 feet. Larger diameters and longer lengths can certainly be accommodated and are used in many applications. Synthetic winch lines can be used

with winches installed on endless types of equipment and vehicles. Producing a maximum strength-to-weight ratio, synthetic ropes are equally as strong in pulling capacity but up to eight times lighter than steel.

“Synthetic rope is so lightweight that it floats,” Lechtenberg said. “It doesn't store as much energy under load as steel lines do, and they do not have sharp burs so it can be handled without gloves. They are also “torque-neutral”

so a swivel hook or shackle is not needed - your line won’t twist like a steel line.”

Synthetic rope is also available in a rainbow of colors so you can custom match your rope to your vehicle or you can color coordinate your winch lines to their specific capacity or winch controls. Here are a few more benefits from Lechtenberg to consider

with synthetic rope:

- Zero corrosion

- Repairable in the field

- Wear resistant

- Sun resistant

- Impervious to many chemicals

- Low stretch

- Reduced flex fatigue

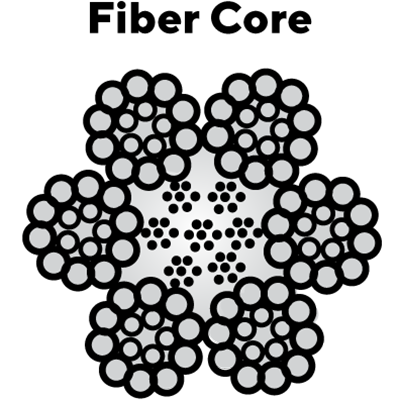

Steel Winch Line Varieties

If you are more of a traditionalist, there are several types of steel winch lines to consider, beginning with Fiber Core wire rope. Made from extra improved plow steel, these winch lines ensure a longer life span by excreting lubricant

under pressure to minimize wear and corrosion on the wire.

Next, Steel Core winch lines are also made with extra improved plow steel, which provides superior strength and flexibility. Steel core winch cables offer greater crush resistance and a higher nominal strength compared to fiber core,

but they are not as flexible as fiber core.

Another type of steel winch line is called Super Swaged. Meaning the rope starts off as the next size bigger but, through a process called swaging, is compressed down to the next size smaller. As a result, the outer wires have a

larger surface area than standard winch lines.

The working load limit remains the same as the original diameter. The compact design offers greater strength than standard winch lines of the same size. Although less flexible, they also provide better resistance to abrasion, kinking and drum crushing.

The last type of winch line to review today is Super Flex wire rope. This type of winch line offers better performance and increased longevity. It does so by containing more wires within a given diameter, resulting in less fatigue.

This makes the line more resistant to wear and tear.

Ordering and Hardware

All of our replacement winch lines include attachment hardware. However, if you need to replace a hook, thimble, clip or socket, we have the parts you need in our Hooks and Hardware department at Zips.com. You can also order any type of the five winch lines described earlier

here as well.

Before you order your new winch line, double-check your winch’s owner’s manual or its identification plate and find the correct wire rope size. It is recommended to follow the winch manufacturers required diameter and lengths. In the towing

and recovery industry, automotive car carriers typically use 3⁄8" rope, medium-duty tow trucks typically use 7⁄16", 1⁄2" or 9⁄16" rope and heavy-duty tow trucks typically use 5⁄8", 3/4" and 7/8” rope.

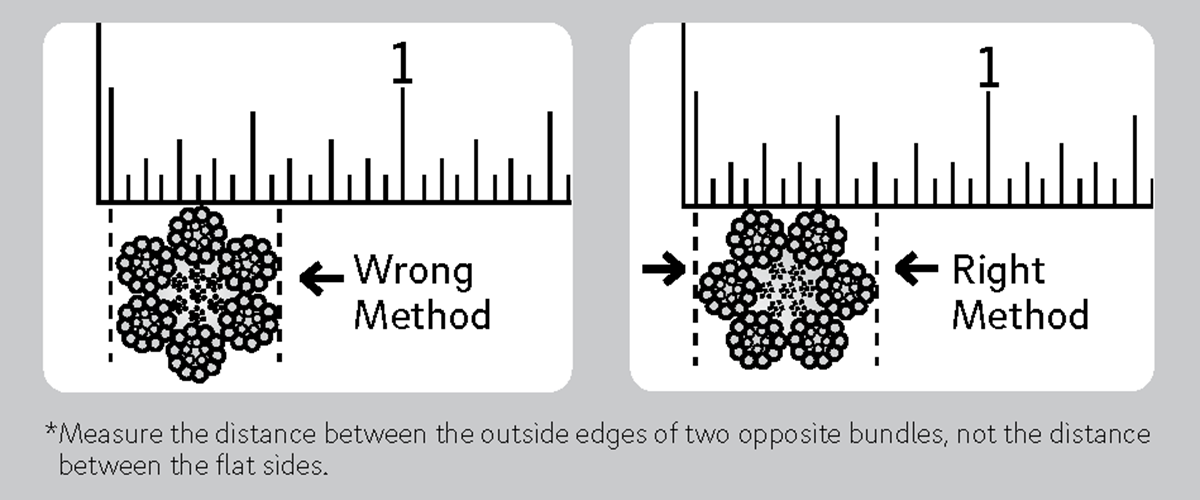

Measure your rope as shown in the diagram above or slip a socket wrench over the plain end for a fast, accurate measurement. Be sure to measure the distance between the outside edges of the two opposite bundles. Not the distance between the flat

sides.

Lastly, consider the appropriate Working Load Limit (WLL) for your winch and recovery efforts. Winch lines are rated by size capacity and Minimum Breaking Strength (MBS). WLL is determined by a safety factor of the MBS. For example, a 3:1 safety

factor means the MBS is three times the WLL.