Winch Cable Hooks and Latches

No winch cable is complete without the hardware to go with it! Zip’s carries winch cable hook latches, winch cable thimbles and winch cable wedge sockets made from B/A Products, All-Grip, Gunnebo-Johnson and Wreckmaster. Find what you are looking for with our latch kits, wedge sockets, wire rope clips and more.

Showing 36 items

- Grade

-

-

- Hook and Latch Type

-

-

- Brand

-

-

-

-

-

-

- Hook Type

-

-

- Type

-

-

-

- Chain Grade

-

- Hardware Type

-

- Hooks & Hardware Type

-

B/A Products Latch Kits

All-Grip Self-locking Swivel Hook G80

Zip's Grade 80 Clevis Self-Locking Hook

Yoke G100 Clevis Self-Locking Hook

Gunnebo-Johnson Safety Latch

All-Grip Sling Hook Latches Grade 100

B/A Products Swivel Hoist Hooks w/ Latches

All-Grip Self-locking Clevis Hook G80

All-Grip Alloy Hooks Swivel

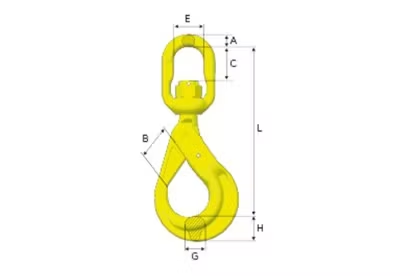

Gunnebo GrabiQ Swivel Safety Hook BKL

| Item # | GI-Z101114 | GI-Z101104 | GI-Z101028 | GI-Z101036 | GI-Z101044 | GI-Z101093 |

|---|---|---|---|---|---|---|

| Code | BKL-6-10 | BKL-7/8-10 | BKL-10-10 | BKL-13-10 | BKL-16-10 | BKL-18/20-10 |

| WLL lb* | 3,306 | 5,700 | 8,800 | 15,000 | 22,600 | 35,300 |

| L | 5.87 | 7.20 | 8.58 | 11.10 | 13.43 | 14.49 |

| B | 1.14 | 1.46 | 1.77 | 2.17 | 2.44 | 2.68 |

| C | 0.91 | 1.06 | 1.46 | 1.93 | 2.56 | 2.76 |

| E | 1.30 | 1.50 | 1.73 | 1.89 | 2.40 | 2.83 |

| A | 0.43 | 0.47 | 0.59 | 0.75 | 0.98 | 1.22 |

| G | 0.59 | 0.67 | 0.83 | 1.18 | 1.46 | 1.73 |

| H | 0.83 | 1.02 | 1.22 | 1.57 | 1.97 | 2.44 |

| Weight lb | 1.54 | 2.65 | 4.41 | 8.82 | 15.87 | 25.13 |

| Fulfills requirements in: EN 1677:2008 (WLL +25%), ASTM A952/A952M and AS 3776:2015. *Safety factor 4:1. All dimensions in inches. |

||||||

Metric

| Item # | GI-Z101114 | GI-Z101104 | GI-Z101028 | GI-Z101036 | GI-Z101044 | GI-Z101093 |

|---|---|---|---|---|---|---|

| Code | BKL-6-10 | BKL-7/8-10 | BKL-10-10 | BKL-13-10 | BKL-16-10 | BKL-18/20-10 |

| WLL tonnes* | 1.5 | 2.6 | 4.0 | 6.8 | 10.3 | 16.0 |

| L | 149 | 183 | 218 | 282 | 341 | 368 |

| B | 29 | 37 | 45 | 55 | 62 | 68 |

| C | 23 | 27 | 37 | 49 | 65 | 70 |

| E | 33 | 38 | 44 | 48 | 61 | 72 |

| A | 0.43 | 0.47 | 0.59 | 0.75 | 0.98 | 1.22 |

| G | 0.59 | 0.67 | 0.83 | 1.18 | 1.46 | 1.73 |

| H | 0.83 | 1.02 | 1.22 | 1.57 | 1.97 | 2.44 |

| Weight kg | 1.54 | 2.65 | 4.41 | 8.82 | 15.87 | 25.13 |

| Fulfills requirements in: EN 1677:2008 (WLL +25%), ASTM A952/A952M-02 and AS 3776:2015. *Safety factor 4:1. All dimensions in mm. | ||||||

Yoke G100 Eye Self Locking Hook

Zip's Grade 100 Eye Self-Locking Hook

All-Grip Self-locking Eye Hook G80

B/A Products Latck Kit - 5/16" Slip Hook

All-Grip Alloy Hooks Eye

Gunnebo Johnson Sling Hooks Eye G80

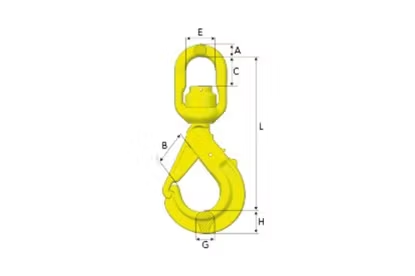

Gunnebo GrabiQ Swivel Safety Hook BKLK

| Item # | GI-Z101116 | GI-Z101106 | GI-Z101030 | GI-Z101038 | GI-Z101046 | GI-Z101095 | GI-Z101294 | GI-Z101295 |

|---|---|---|---|---|---|---|---|---|

| Code | BKLK-6-10 | BKLK-7/8-10 | BKLK-10-10 | BKLK-13-10 | BKLK-16-10 | BKLK-18/20-10 | BKLK-22-10 OS | BKLK-26-10 OS |

| WLL lb* | 3,306 | 5,700 | 8,800 | 15,000 | 22,600 | 35,300 | 44,080 | 60,169 |

| L | 5.87 | 7.20 | 8.58 | 11.02 | 13.35 | 14.49 | 17.17 | 19.13 |

| B | 1.14 | 1.46 | 1.77 | 2.17 | 2.44 | 2.68 | 3.11 | 3.94 |

| C | 0.94 | 1.06 | 1.38 | 1.77 | 2.44 | 2.36 | 3.15 | 4.33 |

| E | 1.30 | 1.50 | 1.73 | 1.89 | 2.40 | 2.83 | 3.15 | 4.02 |

| A | 0.43 | 0.47 | 0.59 | 0.75 | 0.98 | 1.22 | 1.38 | 1.77 |

| G | 0.59 | 0.67 | 0.83 | 1.18 | 1.46 | 1.73 | 1.97 | 2.13 |

| H | 0.83 | 1.02 | 1.22 | 1.57 | 1.97 | 2.44 | 2.44 | 2.68 |

| Weight lb | 1.54 | 2.65 | 4.41 | 8.82 | 16.09 | 25.35 | 37.04 | 57.32 |

| Fulfills requirements in: EN 1677:2008 (WLL +25%), ASTM A952/A952M and AS 3776:2015. For larger sizes, see Classic Grade 8. *Safety factor 4:1. All dimensions in inches. | ||||||||

Metric

| Item # | GI-Z101116 | GI-Z101106 | GI-Z101030 | GI-Z101038 | GI-Z101046 | GI-Z101095 | GI-Z101294 | GI-Z101295 |

|---|---|---|---|---|---|---|---|---|

| Code | BKLK-6-10 | BKLK-7/8-10 | BKLK-10-10 | BKLK-13-10 | BKLK-16-10 | BKLK-18/20-10 | BKLK-22-10 OS | BKLK-26-10 OS |

| WLL tonnes* | 1.5 | 2.6 | 4.0 | 6.8 | 10.3 | 16.0 | 20.0 | 27.3 |

| L | 149 | 183 | 218 | 280 | 339 | 368 | 436 | 486 |

| B | 29 | 37 | 45 | 55 | 62 | 68 | 79 | 100 |

| C | 24 | 27 | 35 | 45 | 62 | 60 | 80 | 110 |

| E | 33 | 38 | 44 | 48 | 61 | 72 | 80 | 102 |

| A | 11 | 12 | 15 | 19 | 25 | 31 | 35 | 45 |

| G | 15 | 17 | 21 | 30 | 37 | 44 | 50 | 54 |

| H | 21 | 26 | 31 | 40 | 50 | 62 | 62 | 68 |

| Weight kg | 0.7 | 1.2 | 2.0 | 4.0 | 7.3 | 11.5 | 16.8 | 26.0 |

| Fulfills requirements in: EN 1677:2008 (WLL +25%), ASTM A952/A952M-02 and AS 3776:2015. For larger sizes, see Classic Grade 8. *Safety factor 4:1. All dimensions in mm. | ||||||||

B/A Products Yoke 1/2" Grade 80 Clevis Self-Locking Hook

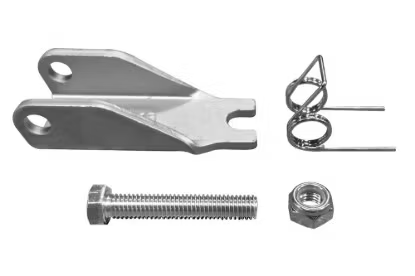

Gunnebo Latch Kit RDEKN

| Item # | Code | Weight lb |

|---|---|---|

| GI-Z100445 | RDEKN- 6 / OKN / RH 1 | 0.07 |

| GI-Z100447 | RDEKN- 7/8 /LKN / RH 2 | 0.11 |

| GI-Z100450 | RDEKN-10 / LKN / RH 3 | 0.13 |

| GI-Z100449 | RDEKN-13 / LKN / RH 5 | 0.29 |

| GI-Z100217 | RDEKN-16 / LKN | 0.44 |

| GI-Z100453 | RDEKN-18/20 | 0.57 |

| GI-Z100452 | RDEKN-22 | 0.93 |

| GI-Z100742 | RDEKN-26 | 1.17 |

| GI-Z100743 | RDEKN-32 | 1.32 |

Metric

| Item # | Code | Weight kg |

|---|---|---|

| GI-Z100445 | RDEKN- 6 / OKN / RH 1 | 0.03 |

| GI-Z100447 | RDEKN- 7/8 /LKN / RH 2 | 0.05 |

| GI-Z100450 | RDEKN-10 / LKN / RH 3 | 0.06 |

| GI-Z100449 | RDEKN-13 / LKN / RH 5 | 0.13 |

| GI-Z100217 | RDEKN-16 / LKN | 0.20 |

| GI-Z100453 | RDEKN-18/20 | 0.26 |

| GI-Z100452 | RDEKN-22 | 0.42 |

| GI-Z100742 | RDEKN-26 | 0.53 |

| GI-Z100743 | RDEKN-32 | 0.60 |

Yoke 5/8" G100 Self-Locking Swivel Hook w/ Ball-Bearing Swivel

B/A Self Locking Swivel Hook, Grade 80, 5/16"

Crosby Clevis Self Locking Hook Grade 100

Gunnebo GrabiQ Safety Hook BKG

Available in the following sizes

| Item # | Size | WLL |

|---|---|---|

| GI-Z101100 | 5/16" | 5,700 lbs. |

| GI-Z101026 | 3/8" | 8,800 lbs. |

| GI-Z101034 | 1/2" | 15,000 lbs. |

| GI-Z101042 | 5/8" | 22,600 lbs. |

| GI-Z101091 | 3/4" | 35,300 lbs. |

| GI-Z101110 | 7/32" | 3,306 lbs. |

| GI-Z101098 | 9/32" | 4,500 lbs. |

Crosby S-1326 Positive Locking Alloy Swivel Hooks

Gunnebo GrabiQ Swivel Safety Hook with Griplatch LKBK

Gunnebo GrabiQ Swivel Safety Hook with Griplatch LBK

B/A Self Locking Clevis Hook, Grade 80, 1/2"

Gunnebo GrabiQ Swivel Latch Hook LKNK

| Item # | GI-Z101349 | GI-Z101350 | GI-Z101351 | GI-Z101352 | GI-Z101354 |

|---|---|---|---|---|---|

| Code | LKNK-7/8-10 | LKNK-10-10 | LKNK-13-10 | LKNK-16-10 | LKNK-22-10 |

| WLL lb* | 5,700 | 8,800 | 15,000 | 22,600 | 44,080 |

| For chain dim. | 9/32, 5/16 | 3/8 | 1/2 | 5/8 | 7/8 |

| L | 6.06 | 7.52 | 9.29 | 11.54 | 15.75 |

| B | 1.10 | 1.38 | 1.57 | 2.09 | 2.91 |

| C | 1.10 | 1.38 | 1.77 | 2.44 | 3.15 |

| E | 1.50 | 1.73 | 1.89 | 2.40 | 3.15 |

| A | 0.47 | 0.59 | 0.75 | 0.98 | 1.38 |

| G | 0.71 | 0.91 | 1.10 | 1.34 | 1.69 |

| H | 0.94 | 1.22 | 1.50 | 1.69 | 2.64 |

| Weight lb | 1.98 | 3.53 | 7.28 | 12.3 | 31.5 |

| Fulfills requirements in: EN 1677:2008 (WLL +25%), ASTM A952/A952M and AS 3776:2015. *Safety factor 4:1. All dimensions in inches. | |||||

Metric

| Item # | GI-Z101349 | GI-Z101350 | GI-Z101351 | GI-Z101352 | GI-Z101354 |

|---|---|---|---|---|---|

| Code | LKNK-7/8-10 | LKNK-10-10 | LKNK-13-10 | LKNK-16-10 | LKNK-22-10 |

| WLL tonnes* | 2.6 | 4.0 | 6.8 | 10.3 | 20.0 |

| For chain dim. | 7, 8 | 10 | 13 | 16 | 22 |

| L | 154 | 191 | 236 | 293 | 400 |

| B | 28 | 35 | 40 | 53 | 74 |

| C | 28 | 35 | 45 | 62 | 80 |

| E | 38 | 44 | 48 | 61 | 80 |

| A | 12 | 15 | 19 | 25 | 35 |

| G | 18 | 23 | 28 | 34 | 43 |

| H | 24 | 31 | 38 | 43 | 67 |

| Weight kg | 0.9 | 1.6 | 3.3 | 5.6 | 15.1 |

| Fulfills requirements in: EN 1677:2008 (WLL +25%), ASTM A952/A952M-02 and AS 3776:2015. *Safety factor 4:1. All dimensions in mm. | |||||

Gunnebo GrabiQ Swivel Latch Hook LKN

| Item # | GI-Z101345 | GI-Z101346 | GI-Z101347 | GI-Z101348 |

|---|---|---|---|---|

| Code | LKN-7/8-10 | LKN-10-10 | LKN-13-10 | LKN-16-10 |

| WLL lb* | 5,700 | 8,800 | 15,000 | 22,600 |

| For chain dim. | 9/32, 5/16 | 3/8 | 1/2 | 5/8 |

| L | 6.10 | 7.56 | 9.37 | 11.61 |

| B | 1.10 | 1.38 | 1.57 | 2.09 |

| C | 1.10 | 1.46 | 1.85 | 2.56 |

| E | 1.50 | 1.73 | 1.89 | 2.40 |

| A | 0.47 | 0.59 | 0.75 | 0.98 |

| G | 0.71 | 0.91 | 1.10 | 1.34 |

| H | 0.94 | 1.22 | 1.50 | 1.69 |

| Weight lb | 1.76 | 3.31 | 6.83 | 11.7 |

| Fulfills requirements in: EN 1677:2008 (WLL +25%), ASTM A952/A952M and AS 3776:2015. *Safety factor 4:1. All dimensions in inches. |

||||

Metric

| Item # | GI-Z101345 | GI-Z101346 | GI-Z101347 | GI-Z101348 |

|---|---|---|---|---|

| Code | LKN-7/8-10 | LKN-10-10 | LKN-13-10 | LKN-16-10 |

| WLL tonnes* | 2.6 | 4.0 | 6.8 | 10.3 |

| For chain dim. | 7, 8 | 10 | 13 | 16 |

| L | 155 | 192 | 238 | 295 |

| B | 28 | 35 | 40 | 53 |

| C | 28 | 37 | 47 | 65 |

| E | 38 | 44 | 48 | 61 |

| A | 12 | 15 | 19 | 25 |

| G | 18 | 23 | 28 | 34 |

| H | 24 | 31 | 38 | 43 |

| Weight kg | 24 | 1.5 | 3.1 | 5.3 |

| Fulfills requirements in: EN 1677:2008 (WLL +25%), ASTM A952/A952M-02 and AS 3776:2015. *Safety factor 4:1. All dimensions in mm. |

||||

Gunnebo GrabiQ Shank Safety Hook BKT

| Item # | GI-Z1011020 | GI-Z1010710 | ||

|---|---|---|---|---|

| Code | BKT-7/8-10 | BKT-13-10 | ||

| WLL lb* |

5,700 | 15,000 | ||

| A | 4.37 | 6.30 | ||

| L | 1.46 | 2.17 | ||

| B | 1.85 | 3.03 | ||

| E | 0.94 | 1.34 | ||

| F | 0.51 | 0.79 | ||

| G | 0.67 | 1.18 | ||

| H | 1.02 | 1.54 | ||

| Weight lb | 1.98 | 6.61 | ||

| Fulfills requirements in: EN 1677:2008 (WLL +25%), ASTM A952/A952M and AS 3776:2015. d min = the smallest permitted shank dimension after machining. Note! After machining of the shank, proof loading must be carried out. *Safety factor 4:1. All dimensions in inches. |

||||

Metric

| Item # | GI-Z1011020 | GI-Z1010710 | ||

|---|---|---|---|---|

| Code | BKT-7/8-10 | BKT-13-10 | ||

| WLL tonnes* |

2.6 | 6.8 | ||

| L | 111 | 160 | ||

| B | 37 | 55 | ||

| L1 | 47 | 77 | ||

| D | 24 | 34 | ||

| dmin | 13 | 20 | ||

| G | 17 | 30 | ||

| H | 26 | 39 | ||

| Weight kg | 0.9 | 3.0 | ||

| Fulfills requirements in: EN 1677:2008 (WLL +25%), ASTM A952/A952M and AS 3776:2015. d min = the smallest permitted shank dimension after machining. Note! After machining of the shank, proof loading must be carried out. *Safety factor 4:1. All dimensions in mm. |

||||

Gunnebo GrabiQ Safety Hook BKD

| Item # | GI-Z101154 | GI-Z101155 | GI-Z101156 |

|---|---|---|---|

| Code | BKD-13-10 | BKD-16-10 | BKD-18/20-10 |

| WLL lb* |

15,000 | 22,600 | 35,300 |

| A | 0.79 | 1.02 | 1.18 |

| L | 8.15 | 10.00 | 11.38 |

| B | 1.73 | 1.89 | 2.24 |

| E | 1.73 | 2.20 | 2.36 |

| F | 0.63 | 0.79 | 0.87 |

| G | 1.18 | 1.46 | 1.73 |

| H | 1.57 | 1.97 | 2.44 |

| Weight lb | 7.05 | 12.79 | 20.06 |

| Fulfills requirements in: EN 1677:2008 (WLL +25%), ASTM A952/A952M and AS 3776:2015. *Safety factor 4:1. All dimensions in inches. | |||

Metric

| Item # | GI-Z101154 | GI-Z101155 | GI-Z101156 |

|---|---|---|---|

| Code | BKD-13-10 | BKD-16-10 | BKD-18/20-10 |

| WLL tonnes* |

6.8 | 10.3 | 16.0 |

| A | 20 | 26 | 30 |

| L | 207 | 254 | 289 |

| B | 44 | 48 | 52 |

| E | 44 | 56 | 60 |

| F | 16 | 20 | 22 |

| G | 30 | 37 | 46 |

| H | 40 | 50 | 62 |

| Weight kg | 3.2 | 5.8 | 9.1 |

| Fulfills requirements in: EN 1677:2008 (WLL +25%), ASTM A952/A952M-02 and AS 3776:2015. *Safety factor 4:1. All dimensions in mm. | |||

Winch Cable Hooks and Latches: Secure Your Winch Lines

A properly attached winch cable is only as strong as the hooks and latches securing it. Whether you’re outfitting a tow truck, industrial vehicle, or off-road rig, selecting high-quality winch cable hooks and winch cable latches ensures safe and reliable operation. From self locking hooks to wire rope clips and synthetic rope thimbles, these accessories provide secure attachment points and prevent accidental releases during heavy-duty pulls.

Why Choose Winch Cable Hooks and Latches

Investing in durable hooks and latches for your winch cables offers multiple advantages:

- Enhanced Safety: Self-locking hooks and properly rated latches prevent accidental disengagement, protecting both operators and equipment.

- Versatile Compatibility: Many hooks, latches, and thimbles are compatible with steel wire rope and synthetic rope, allowing flexibility across winch applications.

- Durable Materials: Top brands like B/A Products, All-Grip, Samson, Gunnebo, and Esmet manufacture hooks and latches with hardened steel or corrosion-resistant finishes for long-lasting performance.

- Simplified Operation: Swivel hooks, wedge sockets, and wire rope clips make connecting and adjusting winch cables quick and straightforward.

Best-Selling Winch Cable Hooks and Latches

Popular products we carry include:

- B/A Products Latch Kits – Complete kits with safety latches for wire rope and synthetic cable.

- All-Grip Self-locking Swivel Hook G80 – Heavy-duty hook with swivel action for secure attachment.

- All-Grip Wire Rope Clips – Essential for forming eyes and securing wire rope ends.

- Zip's Synthetic Rope Thimble – Protects synthetic ropes and prevents excessive wear at attachment points.

Additional components include wedge sockets, safety latches, and other winch cable attachments to suit any professional or recreational application.

Winch Cable Hooks and Latches Shopping Guide

When selecting hooks, latches, and cable end fittings, keep these factors in mind:

- Load Rating – Always match the hook or latch rating with your winch cable’s working load limit.

- Compatibility – Confirm that hooks, clips, and thimbles work with your cable diameter and rope type, whether steel or synthetic.

Attachment Type – Self-locking hooks and swivel hooks simplify connection and improve safety. - Maintenance – Inspect hooks, latches, and clips regularly for wear, corrosion, or deformation, and replace as needed.

- Application – Consider the intended use (industrial, recovery, towing, off-road, or trailer use) when selecting hardware to ensure durability and reliability.

Winch Cable Accessories

Enhance the functionality and safety of your winch lines with winch cable accessories, including clips, thimbles, wedge sockets, and latch kits. Using these accessories in combination with proper hooks and latches maximizes both safety and cable longevity.

Helpful Resources

For more tips on choosing and maintaining winch lines and accessories, check out our blog:

- Choosing & Caring for Winch Lines – Learn best practices for inspecting, lubricating, and safely using your winch cables and accessories.

FAQ: Winch Cable Hooks and Latches

What is a self-locking hook?

A self-locking hook automatically closes and secures the hook opening, preventing accidental cable release during heavy-duty operations.

How do I attach a hook to my winch cable?

Use the appropriate cable end, thimble, or wire rope clip to create a secure loop, then connect it to a self-locking or swivel hook rated for the cable’s working load.

Can hooks and latches be used on synthetic ropes?

Yes, many hooks, thimbles, and latches are compatible with both synthetic and steel winch cables. Always check manufacturer specifications.

How do I maintain winch cable hooks and latches?

Regularly inspect for wear, corrosion, or deformation. Apply a light coating of lubricant on metal components to prevent rust and ensure smooth operation.

What accessories are essential for safe winch cable operation?

Wire rope clips, thimbles, wedge sockets, and latch kits complement hooks and self-locking mechanisms to ensure secure, reliable cable connections.