How to Choose a Winch: Sizes, Motors & Gears

Winches are designed to reduce the workload in many industrial settings and preserve the fun in most off-road recreational activities. Through gear reduction and auxiliary power, they provide extra pulling strength when and where you need it most. This can be off the trail, in the ditch, on the farm or in the water.

In our previous blog, we looked at the different types of winch lines available. Today, we are going to discuss the various options to consider when you want to purchase a new winch. While recognizing the convenience of manual and portable units, we will focus our attention in this blog on the different varieties of permanently-mounted winches available at Zip’s AW Direct:

- Power: Hydraulic or electric

- Drive: Planetary or worm gear

- Capacity ratings: Line and speed

- Spool direction: Overwind or underwind

Hydraulic planetary winches can be rated as high as 130,000 lbs. However, for the daily demands of towing and recovery, 30,000-lb. rated winches can typically handle the job.

Electric winches stocked by Zip’s are normally used in light-duty applications and range in capacity between 1,000 lbs. and 15,000 lbs.

Electric or Hydraulic

Running off AC or DC power, an electric winch is generally easier to install and operate. Off-road enthusiasts such as ATVers and UTVers rely on the vehicle's battery to power the motor. This is useful for self-recovery if they get into trouble off the trail. Weekend mariners also use electric winches to load their boats onto trailers and to control their sails out on the water.

However, this type of winch requires constant power to operate and needs rest between duty cycles. Conversely, a hydraulic winch requires a pump and additional plumbing to supply oil pressure to the winch motor but offers a longer running time. The trade-off for these additional hoses and components is increased power, improved durability and quieter operation.

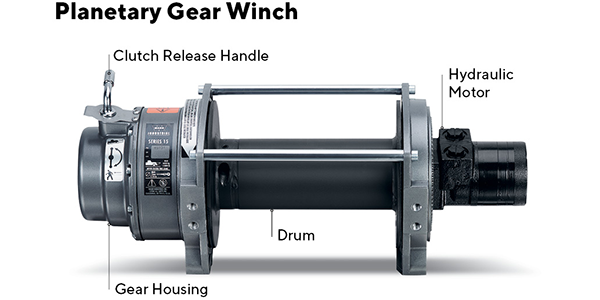

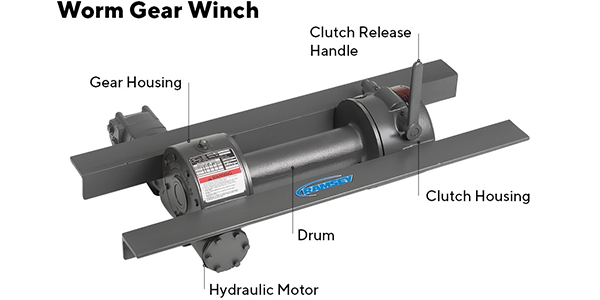

Planetary or Worm Gear

Winches produce their pulling power through gear reduction. Although rotating at a higher rate, the motor doesn’t have to work as hard with a larger reduction ratio. This ratio counts the number of times the motor is required to spin to get the shaft and the winch drum to make one revolution.

A planetary gear borrows its name from the solar system. A “sun” gear is connected to the center shaft of the winch motor which then transfers torque to smaller gears “orbiting” around the sun. The smaller gears engage an outer ring gear to turn the drum. This multiple gear configuration translates to greater pulling power and speed.

A worm gear consists of a cylindrical bar or worm screw with a spiral thread that drives a toothed gear. The hydraulic worm gears offered at Zips.com can pull up to 30,000 lbs., while electric worm gears can pull up to 9,000 lbs. A worm gear has a low transfer efficiency, increased gear reduction and much slower line speed.

Line Ratings and Speed

As stated earlier, winches are rated for their pulling capacity and line speed. They are the first factors you should consider when purchasing a winch. The maximum pull for a given winch is based on the first layer of spooled line and diminishes by approximately 10 to 12 percent for each additional layer of rope.

When sizing your winch, you will need to determine which layer will do the most work in your application. The following example of reduced capacity is based on five layers of 3/8” steel rope on an 8,000-lb. rated winch:

- First layer: 8,000 lbs.

- Second layer: 6,700 lbs.

- Third layer: 5,700 lbs.

- Fourth layer: 5,000 lbs.

- Fifth layer: 4,500 lbs.

According to Ramsey Winch, the rated line pull of the winch must be high enough to pull your vehicle’s gross vehicle weight (GVW.) It also must overcome resistance when stuck or on an incline. This particular winch manufacturer recommends a rated line pull at least 25% greater than your GVW. This helps account for any additional weight–like fuel–in the vehicle you are recovering.

Winches are also rated for line speed, rope diameter and length. Hydraulic planetary winches tend to have a faster line speed, which can be critical to getting tow operators off the road in a timely manner.

Line speeds are typically measured in feet per second under minimal load. For hydraulic units, the flow of hydraulic fluid to the drive—usually 15 gallons per minute maximum--determines the line speed rating.

Spool Direction

Winch lines can also be spooled in an underwind or overwind direction, and winch motors are positioned in either a lefthand or righthand configuration with forward and reverse controls, depending on model. Each winch has a clutch to engage for operation or disengage for free-spooling. Please refer to the winch’s owner’s manual or the rotation decal affixed to the winch housing for proper spool direction.

There are a number of factors to consider when purchasing your next winch. We hope this blog helps in the decision-making process. Be sure to follow manufacturer instructions for installation and maintenance of your new winch. Here are some good tips to follow to ensure a long lifespan, regardless of type and size of winch you choose to purchase:

- Lubricate grease fittings on winch, housing and drum monthly.

- Check hydraulic oil level and electrical connections weekly.

- Scan winch line for flat spots, stress and fraying daily.

- Avoid bird’s nesting with power wrapping and cable tensioner.

- Inspect mounting bolts and tighten as necessary

%20blog%20thumbnail.png)

%20blog%20thumbnail.png)